HCWP/HCWL HORIZONTAL DISC(SPIRAL) DRYER

HCLJ PLATE CONTINOUS CRYSTALLIZER \ HCJJ PLATE INTERMITTENT CRYSTALLIZER

Overview

As we all know, there are many types of drying equipment currently being produced and used in China, such as spray dryer, fluidized bed dryer, airflow dryer, target vacuum dryer, double cone rotary vacuum dryer,coulter vacuum dryer, etc. Most of these devices have the disadvantages of high energy consumption, low thermal efficiency,and long drying cycle.In order to solve the above problems,our company developed this horizontal disc (spiral) dryer.

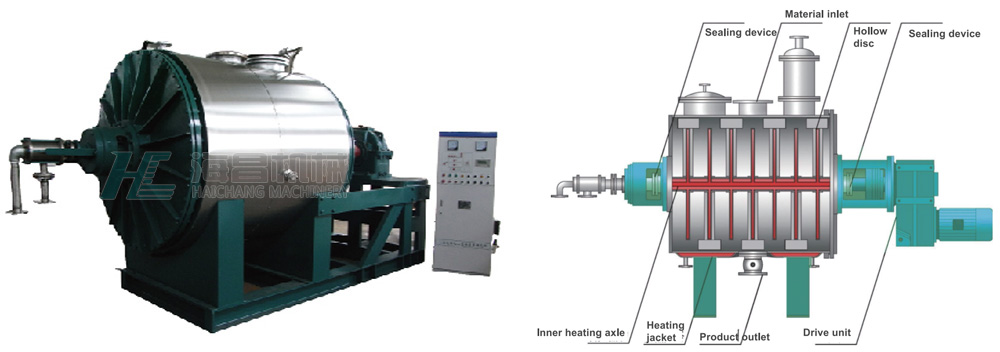

Structure and operating principle

The main structure of the machine is shown in the figure.In a horizontal container with a jacket, a hollow shaft and a plurality of hollow disc (or spiral) stirring devices and a stirring mechanism are installed.These hollow discs (or spiral) are stirred.The device rotates with the hollow shaft and the stirring mechanism under the driving of the driving device.When drying,the equipment is preheated first,and the material is added from the top of the equipment. The new shape of the stirring structure can be controlled by the program to make the material in the machine move back and forth in the axial direction and stir well.and the unique hollow disc (or spiral) is stirred.Together with the iacket of the cylinder. the heat medium canbe effectively circulated in the machine,and the water vapor or solvent evaporated from the material heat exchange is eficiently removed by vacuum through the top dust filter to achieve the purpose of drying, When the material is discharoed. the botom secial structure is automatically opened without a cead angle discharge valve through the stirring mechanism on the disc (or the spiral belt). Drain the dry powder material out of the equipment.

Main features

1.Airtight oneration,especiallv suitable for dangerous products that are flammale, explosive,toxic or highly toxic.

2.In addition to the jacket heating, the disc (or spiral) also heats the material, and the heating area is 3 to 5 times that of the double cone rotary vacuum dryer and the target vacuum dryer of the same volume.

3.The special agitation structure can make the material fully and uniformly stirred in the machine and the heatexchange efficiency is extremely high.

4.Drying under vacuum greatly reduces the boiling point of the solvent, which is beneficial to the recovery of thesolvent.

5.Fully automated control, low labor intensity and good operating environment.

Applicable Scope

The device is mainly used for recovering solvent and discharging powder material after drying, it is also used in the treatment of MVR multi-effect evaporator tail liquid discharge, it’s widely used in fine chemicals, biochemical, pharmaceutical, food, mining, Metallurgy, textile, printing and dyeing industries.

Specifications and technical parameters

Model ITEM | HCWP-0.5 HCWL-0.5 | HCWP-0.8 HCWL-0.8 | HCWP-1.0 HCWL-1.0 | HCWP-1.5 HCWL-1.5 | HCWP-2.0 HCWL-2.0 | HCWP-3.0 HCWL-3.0 | HCWP-4.0 HCWL-4.0 | HCWP-5.0 HCWL-5.0 | |

| Volume(m3) | 0.5 | 0.8 | 1.0 | 1.5 | 2.0 | 3.0 | 4.0 | 5.0 | |

| Heat exchange area(m2) | 7.5 | 10.2 | 12.5 | 15 | 17.2 | 26 | 32 | 38 | |

| Drying method | Atmospheric pressure drying and vacuum tight drying | ||||||||

| Motor power(Kw) | lt's able to selection between 3~55Kw according to different nature of materials. | ||||||||

| Material | Carbon steel. stainless steel, hastelloy. etc | ||||||||

Dimension | OD | Φ900 | Φ1000 | Φ1200 | Φ1400 | Φ1500 | Φ1800 | Φ1900 | Φ2000 |

| Height | 3000 | 3000 | 3200 | 3400 | 3900 | 4500 | 5000 | 5500 | |

| Weight(T) | 1.68 | 2.28 | 3.46 | 4.12 | 5.26 | 7.8 | 9.1 | 10.25 | |

| Others | According to user requirements, users can order equipmentof various specifications from 01 to 6m3 | ||||||||