HCLJ/HCJJ PLATE CONTINOUS(INTERMITTENT) CRYSTALLIZER

HCLJ PLATE CONTINOUS CRYSTALLIZER \ HCJJ PLATE INTERMITTENT CRYSTALLIZER

Overview

As we all know, the cooling and crystallization of materials is a very important unit operation in the pharmaceutical, chemical, food and other industries. The quality of the crystals directly affects the output and quality of the products.At present, the most used in China is the kettle crystallizer, which has many disadvantages:

Since the jacket is cooled, the crystallization starts from the wall of thekettle first, so that the crystal is first formed on the wall of the kettle.in severecases, a thick crystal can be formed on the wall of the kettle, which greatlyaffects the heat transfer efficiency, although the stirring can be improved.The method of rotating speed reduces the problem of crystal wall on the wall of the kettle, but in many cases, the crystallization is also limited by thestirring speed. The stirring speed is too fast, which will greatly reduce thegrain size and affect the next step of washing and washing. It is not suitablefor occasions where it is desired to obtain larger grains. In addition, the kettle is stirred and crystallized, and the stirring paddle is generally difficult to scrape and stir, so that it is difficult to scrape the crystal grains which are formed on the wal of the kettle. thereby aftecting the heat transter eftect.

The ordinarv crvstallizing kettle tends to have a better crvstalization effect near the external cooling kettle wall.and the material near the center of the kettle crystallizes slowlycausing grain unevenness and the overallcrystallization speed is very slow.

For the crystallizer in which the cooling coil is added to the ketle, although the cooling area can be greatly improved, since the cooling coil is stationary, crystals are formed outside the stationary coi during crystallization,which seriously affects the heat transfer effect. in addition, the addition of the coil will greatly affect the stiring effect of the crystallizer, and the scraping and stirring is even more impossible. After forming more crystals on the wall of the kettle and on the coil, the heat transfer effect is worse, and the crystal slurry is not easy to be completely discharced.

Since the bottom of the crystalizer is often a standard elliptical head, the crystallzer with higher material concentration and more crystalline solids is often incompletely discharged, and some of the crystalline solids will remain in the kettle, which will affect the yield and eneray consumption.To this end, our company has developed this high-efficiency plate-type crystallizer, which solves all of the above problems.

Structure and operating principle

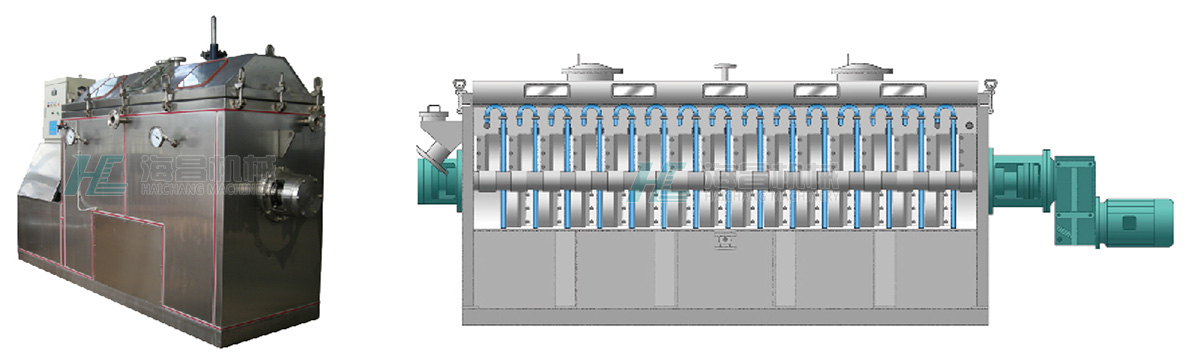

The equipment uses a brand new structure and working principle, thelir main structure is shown in the figure below. A plurality of hollow cooling plates are arranged in a horizontal long trough container, and a central agitating shaft passes through all the cooling plates, and a choke type separating disc is installed between each two hollow cooling plates. Many rotary wheels propel the scrapina type stiring device, and the scraping wall agitating causes all the cooling surfaces to function as a clear wall, so that the heat transfer and cooling efficiency are greatly improved. The material to be crystallized enters from one end,and is moved back to the zigzag and slowly pushed forward to the other end to overflow. so that the material and the large number of cooling surfaces are in full contact,and rapidly cooled to achieve true rapid continuous crystallization.lt can also be designed into rapid batch crystallization according to needs. The stirring speed and crystallization speed can be controlled arbitrarily to obtain the ideal crvstal grain size. For the case of sweating and crystallization, the hollow cooling plate can be quickly cooled by a large number of hollow plates. Crystals are formed between them, then heated to sweat, and the impurities are removed and finally dissolved to obtain a product of high purity.

Main features

1、Since a large number of hollow cooling plates are arranged in a U-shaped horizontal long troughcontainer, the cooling area is generally 5 to 20 times that of the same volume of the kettle crystallizer,and the cooling area is very large.

2、There is a cooling surface not far from all the space in the crystallizer, no cooling dead angle, and thematerial is crvstallized evenlv.

3、All the surfaces have clearing and stirring propelling scraper, which greatly improves the cooling eficiency of the material in the crystallization process, realizing rapid cooling and crystallization, so that one of this crystallizer can replace more than ten or more kettle crystallizers.

4、Realize true continuous crystallization. Since there is always a wall cleaning effect in any process of crvstallization, the heat transfer coefficient and cooling efficiency of the crvstallizer can be maintained at all times, which is impossible for other crystallizers.

Applicable Scope

The equipment is mainly used for crystallization and purification of materials, and is widely used in fine chemicals,bio-chemical, pharmaceutical, food, mining, metallurgy, textile, printing and dyeing industries.

Specifications and technical parameters

Model ITEM | HCLJ-0.5 HCJJ-0.5 | HCLJ-0.8 HCJJ-0.8 | HCLJ-1.0 HCJJ-1.0 | HCLJ-1.5 HCJJ-1.5 | HCLJ-2.0 HCJJ-2.0 | HCLJ-3.0 HCJJ-3.0 | HCLJ-4.0 HCJJ-4.0 | HCLJ-5.0 HCJJ-5.0 | HCLJ-6.5 HCJJ-6.5 | |

| Fill volume(m3) | 0.5 | 0.8 | 1.0 | 1.5 | 2.0 | 3.0 | 4.0 | 5.0 | 6.5 | |

| Cooling area(m2) | 6.3 | 1.0 | 12.5 | 16 | 22 | 28 | 36 | 46 | 68 | |

| Crystallization method | Atmospheric pressure,pressure or vacuum sealed wallcontinuous crystallization or batch crystallization | |||||||||

Dimension | l | 3600 | 4000 | 4500 | 5000 | 5500 | 5700 | 6600 | 6800 | 7400 |

| w | 800 | 800 | 1000 | 1000 | 1200 | 1300 | 1500 | 1600 | 1700 | |

| H | 1300 | 1500 | 1700 | 1800 | 1800 | 2000 | 2300 | 2400 | 2500 | |

| Motor power(Kw) | It's able to selection between 2~45Kw according to different nature of materials. | |||||||||

| Material | Carbon steel, stainlesss steel, hastelloy, etc. | |||||||||

| Weight(T) | 1.68 | 2.28 | 2.86 | 3.62 | 4.66 | 6.92 | 9.69 | 15.25 | 17.85 | |

| Others | According to user requirements,users can order equipmentof various specifications from 01 to 10m3 | |||||||||