HCDY-VACUUM BELT CONTINUOUS DRYER FOR LIQUID

Overview

Belt liquid dryer solves a major problem for the high concentration of alcohol, high viscosity of Chinese medicine extract. In the past using centrifugal spray, because the temperature, heat-sensitive components were destroyed, easy to stick wall.

As for vacuum oven, for a long time, it has high consumption of energy, easy to bacteria and return to tide, it can not be continuous production, and not up to GMP quality standards.

The vacuum belt dryer to overcome the above problems, the drying temperature is low, the active ingredient is not lost, the drying time is short, low energy consumption, no pollution, continuous production, coupled with automatic control, which can effectively guarantee product quality, fully in line with GMP requirements, is a highly efficient, energy-saving, new type of drying unit.

This machine is not only suitable for traditional Chinese medicine extract, but also for polysaccharide drugs, bio-pharmaceuticals, coffee and other products , wide application prospects.

- 13_1_Vacuum-Belt-Continuous-Dryer-For-Liquid_11.pdf(click for download)

Range of application:

Vacuum belt dryer is mainly used in drying many kinds of solid, liquid or paste raw material, such as traditional & western medicines, food, biological products, chemical material, health foods, food additive etc, especially suitable for drying material with high-viscosity, easy agglomeration, or thermoplastic, thermal sensitivity, or material that can not be dried by traditional dryer.

For above materials, Vacuum belt dryer is the best choice:

Pharmaceutical industry: chinese medicine extract, plant extract, egg embryo, fermenting liquid etc

Food industry: food additives, fresh juice, instant coffee, malt extract, carbohydrate, instant beverage, tea powder, cocoa powder, corn paste etc.

Chemical industry: lithium battery, powders, crystals, granules, oxyde, explosive, strongly stimulation and highly toxic material etc.

Work Flow

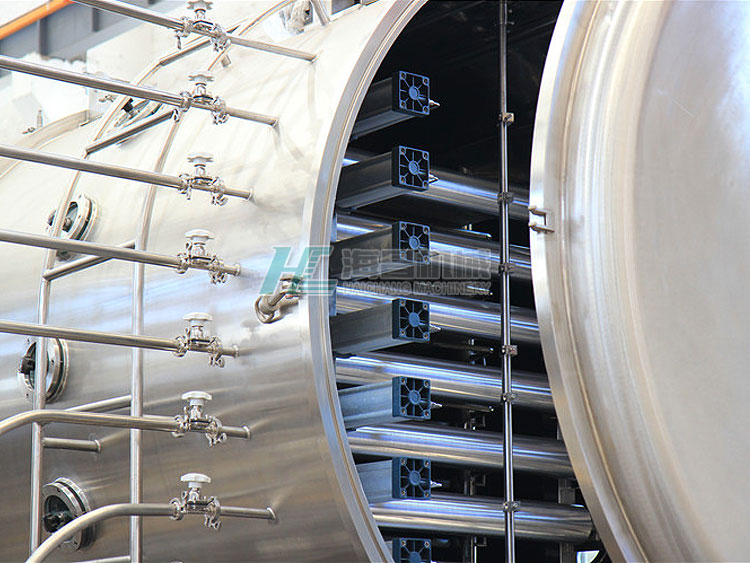

This drying equipment feature is a vacuum chamber where a material conveying guide belt (Teflon PTFE) is installed. Materials are distributed continuously on the guide belt after they pass through the continuous vacuum distributor at the top of the machine (adjustable distribution thickness 3mm-30mm). The guide belt conveys the material slowly to the other end while the heating zone (40℃-180℃) below the belt evaporates moisture within the compound. Evaporated moisture is quickly removed by the vacuum system. The compound automatically falls onto the second layer guide belt when it reaches the end. The process repeats until the desired dryness is achieved. When it is finished, materials will fall into the conveying chute at the discharging end where a screw conveyor will deliver it to other processing equipment to be ground, sieved and pulverized.

Specifications

| HCDY-VACUUM BELT CONTINUOUS DRYER FOR LIQUID | |||||||||||

| Basic Parameters/Model | HCDY3-2 | HCDY6-3 | HCDY20-4 | HCDY35-5 | HCDY70-6 | HCDY100-7 | HCDY135-8 | HCDY160-9 | HCDY200-10 | ||

| Heating Area (㎡) | 3 | 6 | 20 | 35 | 70 | 100 | 135 | 160 | 200 | ||

| Cooling Area (㎡) | 1.5 | 2.5 | 3.5 | 10 | 15 | 20 | 27 | 30 | 35 | ||

| Water Evaporation Capacity (kg/h) | 3~5 | 5~10 | 15~30 | 30~45 | 55~80 | 90~110 | 120~150 | 150~180 | 180~220 | ||

| Number of Drying Bed (layer) | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| Drying Temperature Range (℃) | 40~180 | ||||||||||

| Heating and Cooling Zone | 2 Heating Zone | 3 Heating Zone | 4 Heating Zone | 5 Heating Zone | |||||||

| Cooling Zone | Cooling Zone | Cooling Zone | Cooling Zone | ||||||||

| Moisture Content of the Material Charged (%) | 20~30 | ||||||||||

| Moisture Content of the Dried Charged (%) | ≤ 1~4 | ||||||||||

| Discharging Form | Screwing grinding and sieving (20~200 meshes) with adjustable discharging | ||||||||||

| Heating Media | Superheated water, vapor, conduction oil | ||||||||||

| Equipment Dimensions(mm) | 6500×1900 ×2500 | 7000×2000 ×2500 | 11000×2200 ×2800 | 12500×2200 ×2800 | 12500×2400 ×2800 | 17000×2600 ×3000 | 17500×2800 ×3200 | 18000×3200 ×3200 | 18500×3200 ×3500 | ||

| Total installed power (kw) | 20 | 30 | 35 | 39 | 45 | 50 | 55 | 60 | 67 | ||

| Operating Pressure of the cleaning system (MPa) | 0.5-1.0 | ||||||||||

| Yield of Dried Product (kg/h) | 3~8 | 8~15 | 15~30 | 30~50 | 50~80 | 90~120 | 120~150 | 150~180 | 180~220 | ||

| Notes | ① The yield is calculated based on 70% content at 90℃ drying temperature with dry power containing about ≤4% moisture, in case the dried liquid is water, specific gravity of the dry power is determined to be 1. The yield will be larger if the dried liquid is solvent. | ||||||||||

| ② All technical parameters are for reference only depending on the material conditions, and our company has the right to change them without further notice. | |||||||||||

Features

1. It meets the GMP hygienic requirements to realize drying by finishing continuous charging, continuous discharging and grinding under vacuum condition;

2. It can realize controllable drying temperature(40℃-180℃), unchanged thermal sensitivity of materials, recoverability of 95%solvent as to solvent materials and vacuum drying of oxidizing materials without oxidation;

3. It can finish drying, grinding and granulating under vacuum condition;

4. Continuous discharging starts after 20-60minutes, with product yield up to 99%;

5. Highly sticky materials will not stick to the belt (which is Teflon PTFE), and crystal materials will not damage the crystal form after drying;

6. The moisture content of the dried product can optimize such major parameters as temperature, vacuum degree and speed of the drying process, enabling the utilization of the equipment to achieve the best economic benefit;

7. It adopts PLC automatic programming control system to realize high-degree automation and greatly reduce labor operating costs;

8. Its operating cost is only one third of or even lower than of its similar drying equipment;

9. CIP automatic online cleaning system with various cleaning methods can clean the equipment completely and quickly after drying and meet the GMP requirements;

10. It is suitable for large-scale, continuous and automatic operation.

Comparison between spray dryer and belt vacuum continuous dryer